MARTHERM PPR-C Pipe and Fittings

You can contact us for detailed information about PPR-C pipe. Made of Polypropylene Random Copolymer (Type 3) raw material and resistant to chemicals, Martherm pipes are used in sanitary systems, for the transport of hot and cold fluids.

Produced in accordance with TS 11755, TSE EN ISO 15874-3, TS 9937 standards, PPR-C pipes and fittings are long-lasting. Due to its high temperature and pressure resistance properties, it is the most suitable choice for hot-cold water transfers and heating installations.

Martherm PPR-C Pipe and fittings are produced in white and gray colors, and different colors are also produced on special orders. You can contact us for your questions about PPR-C pipe.

Apart from these products, you can also examine our pvc waste water pipes and pvc clean water pipes products.

PPR-C Pipe Properties;

- Working life of over 20-25°C pressure is 50 years,

- Suitable for use between 20°C and +95°C (Isolation should be applied considering the freezing point of the fluid in the pipe)

- Shows high resistance to chemicals

- Corrosion resistant

- Does not calcify and rust

- Does not change the color, smell and taste of water

- It has slippery and shiny interior surfaces.

- Shows high welding performance

- Provides 70% savings in assembly and no assembly waste

- Provides heat and sound insulation

- Hardly flammable (Ref: DIN 19560 and DIN 4102)

- Environmentally friendly

Issues to be Considered in PPR-C-Pipes and Fittings;

- For turns over 30º, 45º elbow should be used.

- Excessive tightening should be avoided in metal fitting applications, teflon tape should be used instead of hemp.

- Pipes should be cut perpendicular to the pipe axis and with sharp pipe cutters.

- Dirty pipes and fittings should not be welded, deformed and cracked pipes and fittings should not be used.

- Pipes must be protected from all kinds of impact and impact.

- Conical threaded parts should not be used in the connections.

- The installation must be protected against the danger of freezing.

- If the installation will not be used after the test, the water in the installation must be drained against the risk of freezing.

- Welding should not be done if the Teflon on the threads is worn out or broken. (Teflon life is as long as 2-3 residential applications.)

- Welding waiting time should be observed, pipes and fittings should not be rotated during melting.

- Precautions should be taken against steam compression in gas water heater installations.

- Pipe and fittings should not be exposed to direct sunlight for a long time.

- PPR-C raw material does not contain stabilizer for resistance to UV rays. The maximum storage period in the environment in contact with sunlight is six months..

- After the installation, pipes and fittings should be insulated against UV rays and freezing in the sections coming out of the building.

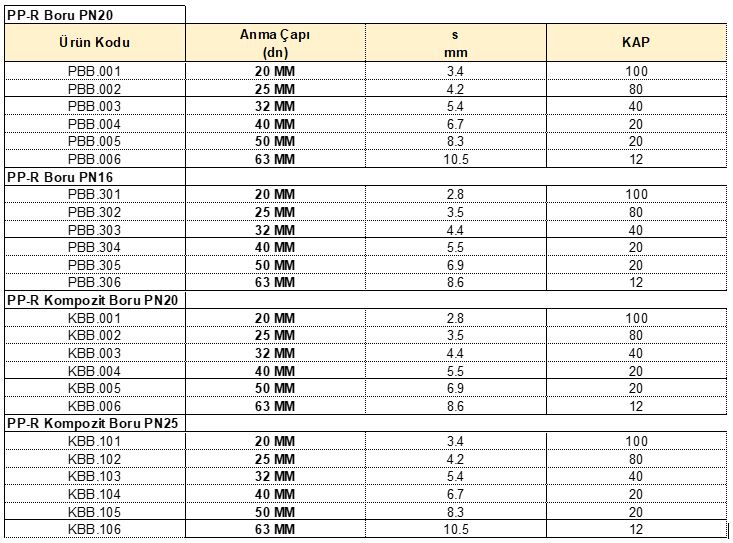

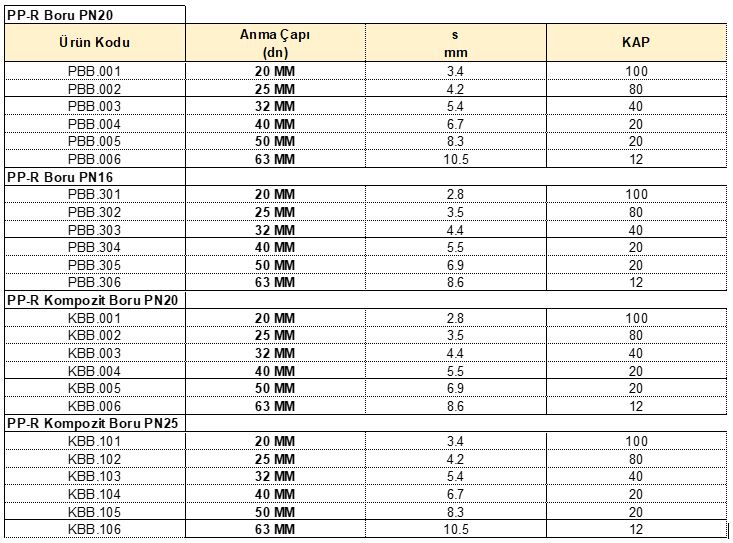

PPR-C Pipe Diameters and Dimensions

You can check the diameters and dimensions of PPR-C Pipes from the table below.