Irrigation Systems

Mardin Pipe is manufactured from high-density polyethylene (HDPE) with increased resistance to sunlight (UV rays) with special additives. 4 and 6 ATM. It produces in diameters of 75, 90, 125, 140, and 160 mm and lengths of 5 meters and 6 meters under pressure. Different sizes can be produced depending on customer demands. In addition, the main line can be produced from PVC.

Sprinkler irrigation systems; thanks to its practical connection (Quick Coupling) design, it provides the customer with a fast, practical, efficient and long-lasting agricultural irrigation opportunity with its light, flexible and high impact resistance. You can call us for your questions about Sprinkler Irrigation Systems.

Apart from these products, you can also examine our PVC clean water pipes and PVC waste water pipes.

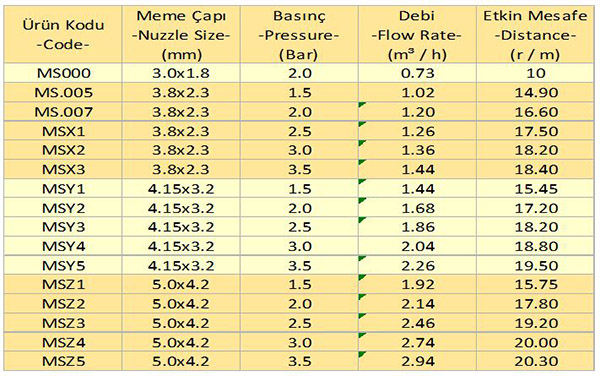

Sprinkler Properties;

- It has a durable body made of high quality raw materials resistant to impacts, sunlight, alkaline waters and thin acids, and a robust mechanism with a stainless steel spring. It operates at 1.5-10 bar water pressures.

- Water spreading pin creates dynamic, strong, fine droplets.

- It has a very comfortable operation feature at low and medium speed at all kinds of pressure with its spring hardness adjustment.

- Thanks to the grooved spray nozzles (4.00 mm, 2,5 mm) it rotates the water and distributes it as powder. This prevents the plant leaves from being beaten.

- Nozzle throw angle 30°, full circle 360°

- The water uniformity rate is high (94%-96%) and it does not form ponds.

- Maximum arrangement range 24x24.

Benefits of Sprinkler Irrigation;

- There is no need for extensive land leveling.

- It provides an increase in crop yield and quality.

- Prevents irrigation water losses.

- Provides ease of irrigation even on sloping lands.

- Fertilizer is delivered to the plant with irrigation water.

- Since water is given in a controlled manner, it does not create a surface drainage problem.

- It provides the opportunity to irrigate in shallow and highly permeable soils without raising the ground water.

- Salt and dust residues on the leaves are easily washed off.

- Provides equal water distribution.

Considerations in Sprinkler Irrigation Pipes;

- After the pressure test in fixed and semi-fixed systems, the sprinkler pipes should be covered.

- Since pressure is required for the system to work, a suitable pump should be preferred.

- Pump connection and pump connection S must be used to the motor pump outlet, otherwise the vibration in the motor pump will directly interfere with the pipe system and will damage the pipe.

- If the motor works with electricity, a ground line must be made.

- Forced movements should not be made while installing the Sprinkler Irrigation Pipes and fittings; fittings and seals must be installed with soapy water. Grease or similar oils should not be used.

- After operating the system at the smallest flow rate, after the lateral and main pipes are filled with water, the pipe line should be cleaned by opening the blind plug for a short time.

- A filtration system suitable for the project should be used to prevent the sprinkler nozzles from clogging.

- Do not operate the system in windy weather for proper distribution or the system should be operated by adjusting the lateral gaps.

- If fertilizer application has been made with the system, the entire system must be washed.

- Before the seals of the pipes are installed, the seal channels must be cleaned.

- In fixed systems, sprinkler pipes should be minimum 45 cm in regions with mild winters, and minimum 80 cm in regions with frost. should be buried deep.

- In the fields where the fixed system is installed, the sprinkler pipes should be buried at a depth that will not be damaged by the agricultural tools used in the field.

- After the irrigation work is completed, the seals should be dried and stored in a box.

- When the season is over in fixed system irrigations, the water in the system should be completely drained.

Transport and Storage

- It should be protected against impacts during loading, unloading and use, should not be thrown from a height and should be stored carefully.

- If the sprinkler irrigation system is to be transported in cold weather, it should be transported carefully so that there is no breakage problem in the pipes.

- If the sprinkler irrigation system is to be transported in hot weather, it should be carried with two people to avoid damage to the middle parts of the pipe.

- Absolutely no agricultural implements, tractors, etc., over the sprinkler pipes and heads. Vehicles must not be passed.

- The sprinkler irrigation system should be kept in suitable storage conditions at the end of the season.

- At the end of the season, additional parts should be carefully separated from each other and stored after cleaning.

Ideal Placement

- The size and shape of the land to be applied, the location of the water source and the location of the pumping station should be taken into account when placing the sprinkler irrigation system on the land. In addition to these, the following rules must be observed in order to make the placement order correctly.

- Place the main pipeline in the direction of the slope dominating the land.

- Place the lateral pipes perpendicular to the prevailing slope and parallel to the leveling curves.

- Place the lateral pipes perpendicular to the prevailing wind direction.

- The pressure variation along the lateral should not exceed 20% of the operating pressure.

- If it is necessary to operate more than one lateral at the same time, preferably one diameter or at most two separate diameters should be used on the laterals.

- The movement order of the laterals on the main line should be arranged in a way that does not cause loss of labor and time.

- Changes in pipe diameters should be made in the main pipelines in order to facilitate pressure regulation.